The CING hot rolling process forecasting system is a software product based on a mathematical model developed using machine learning methods that calculate and predict the following operating parameters of the hot-rolling mill equipment:

The main functions of the system.

The system has a modular structure. This system includes the following features:

- Predicting roll wear and peak loads;

- Calculation of the presets of the rolls of the hot-rolled mill;

- Wide rolling to narrow planning;

- Prediction of slab outlet temperature.

- Calculation of the speed of the roller table to achieve a predetermined temperature (at the intermediate cooling and cooling installation);

- Obtaining parameters of the measured band from the upper level system (Steel grade, tasks ...)

- Visualization of input and calculation data

- Archiving input and calculation data

- Indication of incorrect operation of sensors

- Accounting for the effect of steel grade on the design model

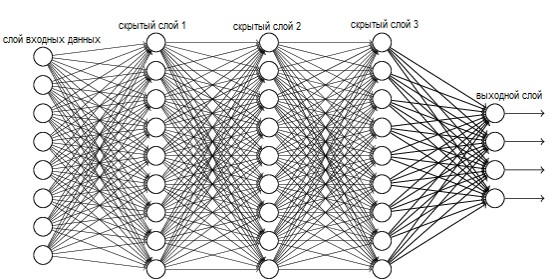

The system is based on a mathematical model. It is based on artificial neural networks, but is not limited to them.

A distinctive feature of neural networks is their ability to learn - that is, to increase their own efficiency based on well-known examples. Therefore, to create a neural network, you must have data with a known result - the so-called training with a teacher.By learning from the available data, the neural network achieves the required accuracy, after which it can be used as a model for calculating parameters in real time.

Pict.2. Multilayer neural network architecture

The CING system provides for preliminary training of the calculation modules at these enterprises. These modules will later receive the necessary data from the top-level system and carry out the calculation of target information, after which this information is archived and access to its analysis is provided.